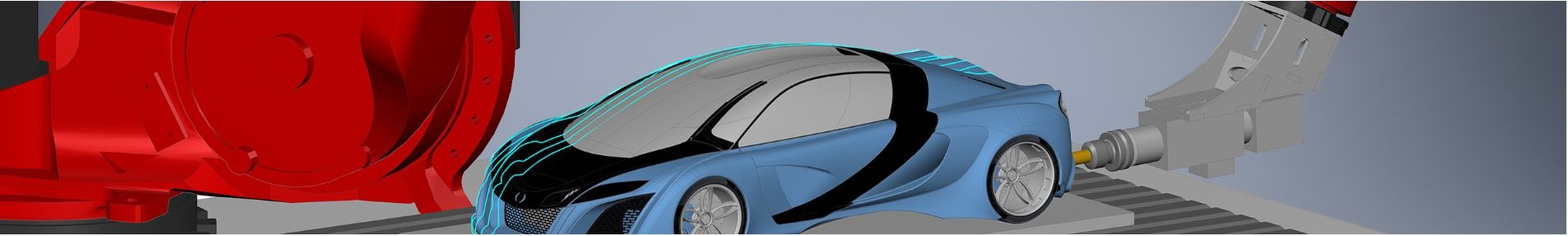

Robotmaster is an offline robot programming and robot simulation software that allows task experts to program their robot quickly and easily from simple to complex tasks while maximizing the robot’s capabilities. Features include:

- accurate robot trajectories without teaching points

- “click-and-drag” interactive simulation/editing environment

- automated robot motion optimization

- multiple robot manufacturers compatibility.

Manufacturing facilities around the globe are adopting automation to maximize their productivity and remain competitive. Manufacturing robots have many advantages such as high accuracy and consistent production which result in a much better ROI in comparison to completing processes manually. However, when it comes to programming – most of the time, they must be offline to be updated or programmed, which means production delays and lost revenue.

Offline Programming (OLP) software allows manufacturers and integrators to generate robotic code in an offline environment (on a computer) and then upload it to the robots without any downtime. OLP software works with 3D CAD models to define tasks such as path planning, programming, and engineering.

The OLP environment utilizes a 3D CAD model of the robot work cell. All the programming is completed in the virtual space, which allows for troubleshooting and problem solving before the robot has been installed. Programs can be created, simulated, and edited in the OLP environment, ensuring that the robot will perform as required. Once the robot code is generated it’s then uploaded to the robot.

Read more about robots offline programming and how it works.

Robotmaster delivers unmatched, full-function off-line programming capability for robots – easy programming of precise robot motion control and quick generation of path trajectories of any size, with minimal programmer intervention.

Singularity, calibration, collisions, reach limitations, and motion granularity are uniquely complex to robotic systems and can make programming particularly cumbersome. Robotmaster’s Interactive Simulation Environment (RISE) provides a unique tool for programming, visualizing and optimizing processes/events quickly and easily.

Read how simulation enhances the offline programming experience.

Robotmaster is the ideal offline robot programming and robot simulation software solution for all applications that require CAD/CAM for robots including: trimming, 3D machining, deburring, polishing, welding, dispensing, grinding, painting…

COLLA SIA is Robotmaster authorized reseller in Latvia, Lithuania and Estonia. COLLA’s specialists provide software implementation, training, consultations and technical support. For consultation on how Robotmaster can facilitate your robot programming please contact Ivo Lipste by e-mail: ivo@colla.lv

Robotmaster offline programming software for robots is a vendor agnostic solution – it generates code for a variety of robot brands:

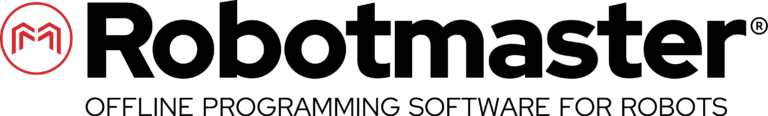

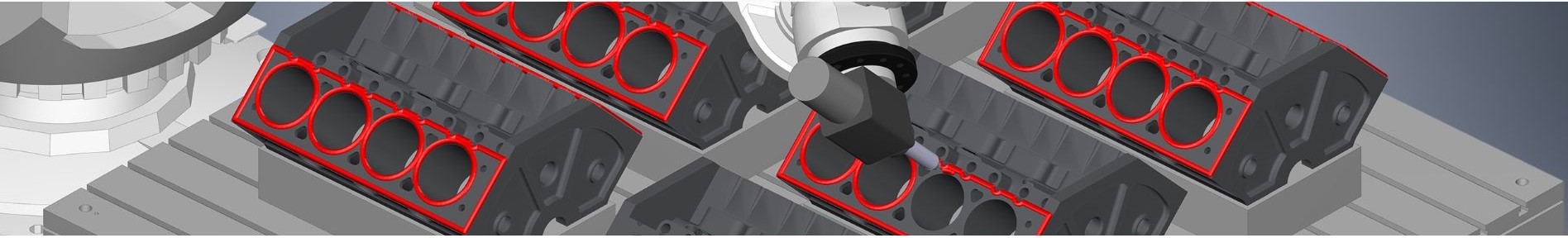

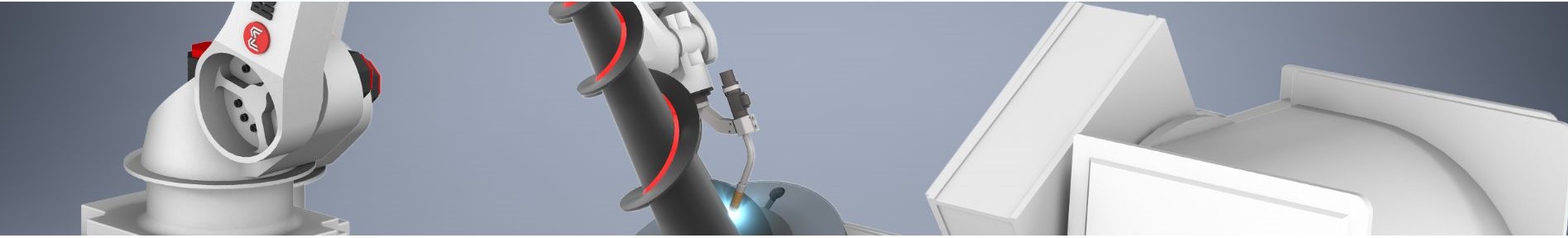

Robotmaster programming applications:

Cutting

Robotic machining

Trimming

Cutting

Welding

Surface grinding and finishing

Dispensing

De-burring

Paint/Spray Coating

Surface treatment

Cooperative robotics

Additive manufacturing

Deflashing

Part to tool

Rail/Rotary

English

English Русский

Русский Latviešu

Latviešu Lithuanian

Lithuanian